It was a wintry Helsinki night in 1959, with an approving beep from Sputnik passing overhead – when four high-school buddies got together and founded a rocket club they named “Sällskapet för Astonautisk Forskning” or SAF for short. The four aspiring rocketeers were Bo Fagerström (Fagu), Peter Heldt (Pede), Georg Stünkel (Jerry) and Juhani Westman (Jussi).

As the new kids on the block our fledgling SAF team was short on both recognition and funding that limited the kinds of rockets our members could realistically hope to build and fly. Also looming in the background was the hurdle of an existing treaty between Finland and the then Soviet Union that prohibited Finland from possessing or launching missiles. But such blocks in the road certainly didn’t dampen the enthusiasm of our spirited group chomping at the bit, as I hope to convey in these vignettes walking you down memory lane through SAF’s formative years:

There was also the time when Peter would use his aerodynamics term paper to write a Fortran-4 program to compute the shape that minimizes the fordrag at supersonic speeds of the von Ka’rma’n ogive for the Alpha rocket’s nose cone. The calculations would run on the Helsinki University of Technology’s (TKK) newly acquired Elliot minicomputer that required the instructions and data to be entered separately on punched tape! After crunching the numbers, the Elliot would print out the spatial coordinates for the optimal ogive from which to fashion the physical nose cone. My personal copy of the 1960 edition of Nielsen’s text Rocket Aerodynamics that guided me through the equations has remained with me through all these years, and leafing through its yellowed pages recognizing my scribbled annotations from almost 60 years ago, brings back dear memories of how much fun we all had working together on the Alpha rocket. It also reminds me of how much I miss my dear late friend Bo (Fagu) who gave the group and SAF so much.

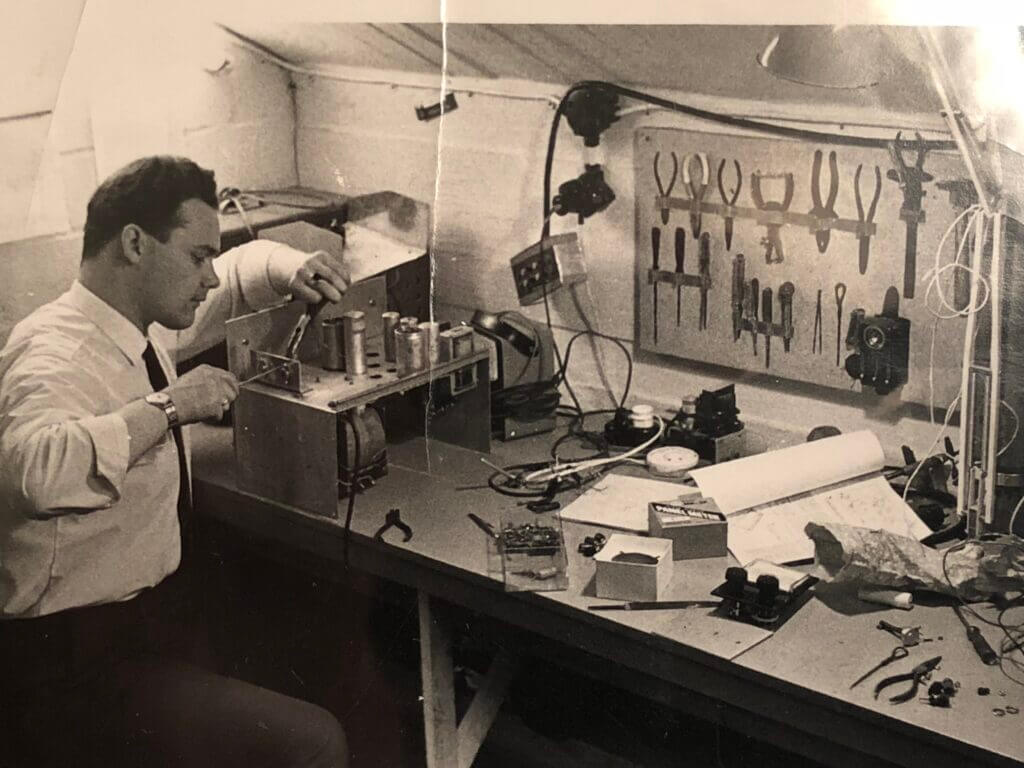

It wasn’t unusual for Bo and Peter to be hanging out at the lab (a rented bomb shelter), pulling all-nighters in front of the blackboard – chalk-in-hand working out the solid propellant thermodynamic characteristics and burn area geometry to produce the desired flat thrust profile that in turn would set the nozzle dimensions for delivering the design thrust for the planned Alpha rocket to reach its target altitude. Back in the 1960s we would perform all our calculations on slide rule. (I still have mine to remind me of those carefree days).

Inspired by Sputnik, and encouraged by Professor Oberth’s book and von Braun’s V2 rocket, our group briefly flirted with the notion of using ethylene alcohol and liquid oxygen for propelling our first-born, the Alpha rocket. Stig Hanne’n actually manage to bring a cryogenic flask containing liquid oxygen into the lab! However, the high cost and the formidable engineering and safety challenges involved soon turned our attention to non-liquid fuel alternatives. NASA’s successes with solid propellant rockets further boosted our confidence in embracing non-liquid options… although we did hold on to the beer!

Bo was able to secure a quantity of the polymer binder/fuel NASA was using in its composite solid propellant rockets, by ordering directly from its US supplier Thiokol. The other components making up our candidate solid propellant included powdered ammonium percolate (oxidizer), aluminum (fuel/stabilizer), iron oxide (catalyst) as well as a curative. We would make aluminum grains from grinding available folie, although atomized aluminum would have been our preference.

Being able to obtain the solid propellant components – at least in quantities adequate for initial static tests – was a first step. Getting to the crucial second step for success would prove harder, and was predicated on our ability to control the combustion chamber pressure throughout the burn time, along with maintaining a near-constant volumetric mass rate, which in turn determined the nozzle design. The team would experiment with different propellant burn area geometries and burn rates (e.g., a star-shape bore changes its area less as the propellant burns, compared to a simple cylindrical bore). We would also try out various ways of improving the mixing process to prevent cracks and air bubbles from forming inside the propellant that could have led to destructive pressure spikes from the sudden inrease in burn area.

A decisive factor to the team’s ultimate success at mastering the exacting second step was the fortuitous availability of the BATES standard published in 1960/61- the acronym standing for BAllistic Test and Evaluation System, which is a standardized system for measuring solid rocket propellant performance designed and developed by the United States Air Force Research Laboratory in 1959 through the early 1960s.

Early casing material candidates our group would explore for potential use in the Alpha rocket, included laminated fibreglass and drawn aluminium pipe. In addressing the nozzle throat ablation challenge, the team would look at using a machined graphite insert or even a complete graphite throat section. The manufacturing of the Alpha rocket nozzle presented a major hurdle for the early SAF rocketeers, as its resolution hinged essentially on the availability of funding and on finding an appropriate fine-machining shop-able and willing do the work.

SAF’s early rockets would undergo static performance testing inside the safety of a remnant World-War II trench located on the outskirts of Helsinki. It proved to be a good choice as the zigzagging trench walls would dissipate the blast wave while shielding the rocketeers from flying shrapnel during a catastrophic engine failure on the test bed.

Around 1963, SAF’s membership enjoyed the addition of several academics, including our physics professor Jucca Fedosow and our chemistry professor von Konow. Other faculty members joined down the road (I am forgetting their names). Astronomer Gustaf Järnefelt became an honorary member in the early 1970s. Collectively these distinguished men of science brought welcomed gravitas and recognition for the society.

To properly understand SAF’s later drift from its original focus on rocketry, starting around the late 1960s, to a concentration on discussion groups and teaching of rocketry and space travel, it is important to appreciate the circumstances that led to this shift in raison d’etre.

Perhaps first and foremost was timing:

Back in 1959, the founders were in their final year of senior high, preparing for college and the mandatory yearlong service in the Finnish military – Georg Stünkel even married early. These newfound priorities would take a big bite out of the group’s available time to devote to rocketry.

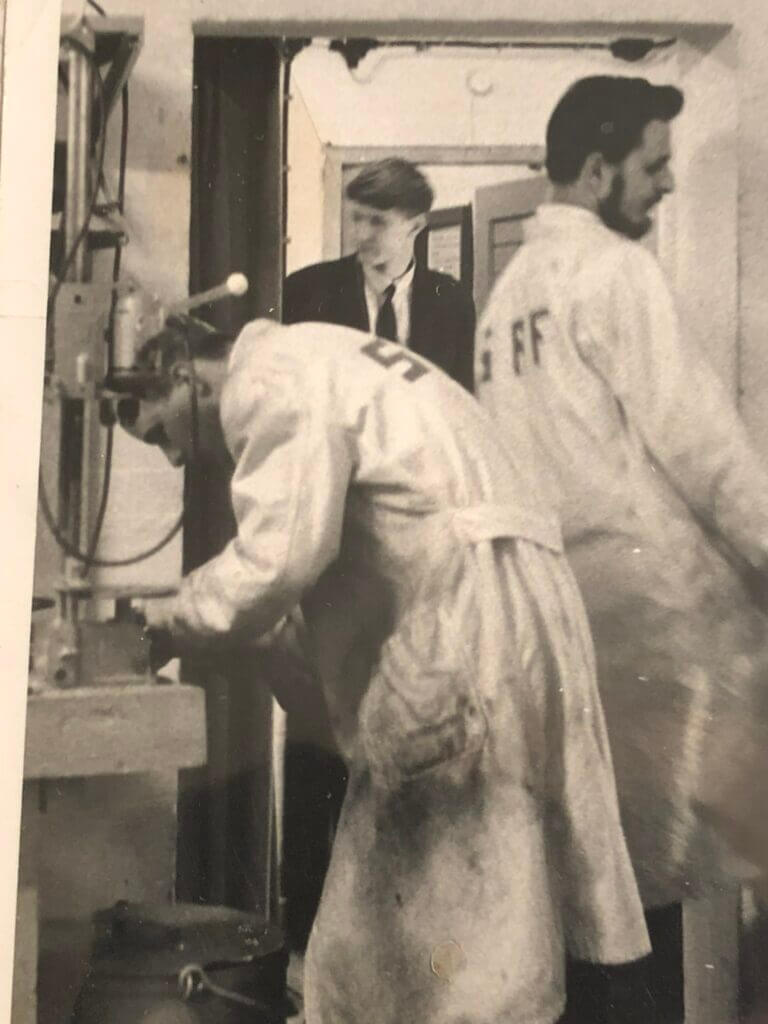

Secondly, SAF’s early rocket work (sometimes with a helping hand from our professors), along with the associated theory, design and engineering, was essentially being carried out by the folks wearing white lab coats in the attached pictures; including Peter Heldt who took the shots. So as this core group began to curtail their active participation in project Alpha by the latter part of the 1960s, rocket building fell fallow.

In hindsight, our eager SAF group of self-taught senior-high students – still in their late teens – may have been forgiven for underestimating the task of lofting a homegrown rocket to the respectable 100 km international boundary of outer space – officially designated as the von Ka’rma’n line. The world had to wait another 40 years to witness the accomplishment of this feat when the American amateur rocket “GoFast” reached an officially verified altitude of 116 km, on May 17, 2004.

The GoFast rocket was developed and launched by a team of civilians calling themselves the Civilian Space eXploration Team (CSXT). The group was created in 1995 and included designers, engineers and other enthusiasts. It enjoyed corporate sponsorship and had the advantage of an established industry of hobbyist rocket suppliers (Apogee, Estes et al). The GoFast rocket’s total development and launch cost is estimated to have been around $200,000 – a good chunk of change for an all-volunteer team, even in today’s money.

Their history-making rocket stood 6 m tall, measuring 25 cm across. It’s ammonium-perchlorate based solid propellant motor produced over 70,000 Newtons of thrust at lift off, propelling the rocket and its 18 kg payload to a maximum velocity of Mach 5.5 in just over 10 seconds. Its canted fins gave it a spin of 8 revolutions per second that kept it stable during the ballistic portion of its near-vertical trajectory. The motor was designated as an S-50000 containing 196 kg of ammonia-perchlorate based propellant configured in a monolithic case-bonded grain with a central fin-o-cyl (star) core with a nearly neutral thrust profile. It delivered a whopping total impulse of 431.6 kNs (note the k for “KILO”).

I was able to reproduce the GoFast rocket’s quoted 116 km max altitude and Mach 5.5 max velocity figures in a spreadsheet I created to model the rocket’s boost and coast altitudes (including drag), and by plugging in the GoFast’s key design parameters quoted above and elsewhere.

Encouraged by the validation of my spreadsheet, I was curious to apply it to estimating the total impulse (ballpark) required to propel the original Alpha rocket to its lower altitude goal of 30 km.

Without remembering the Alpha rocket’s exact design parameters, I made the following working assumptions:

A 10 cm rocket diameter; a 5 kg payload; a conservative specific impulse of 100 seconds (GoFast’s was 224 s);

a propellant mass of 20 kg; and a 2.5 sec burn time. Plugging these values into the spreadsheet produced an apogee of 35 km, a total impulse of 20,000 Ns and a max velocity of Mach 2.7 at burnout. Still a lot of impulse, but perhaps attainable by SAF back in the 1960s, under different circumstances.

I recall our project Alpha’s early test rockets delivering around 400 N of thrust during static testing. Don’t remember the exact burn time while the engine was producing this thrust (flat profile), but it would have been around 3 seconds, yielding an estimated total impulse of around 1,200 Ns. Still an order of magnitude short of the estimated 20,000 Ns needed to reach the Alpha’s lower 30 km altitude goal.

I left Finland in 1971 to pursue a career in the US.

My subsequent interactions with the society consisted in the main of the occasional news update from Bo, Juhani Westman and Stig Hanne’n. Having been a contributor to the original project Alpha, it would be of interest to me to know how far the effort had progressed by the time it was abandoned. Shame on the supplier who dropped the ball on delivering the make-or-break propellant! Incidentally, looking at the shape of the nose cone in the picture you sent me of the 7/9-scale model of the Alpha rocket, it does resemble a von Ka’rma’n ogive. I presume the purpose of the tether is to guide the model until it reaches stable free-flight velocity?

I am heartened by your personal efforts to bring to life the society’s history in documentary form. Atta-boy also for your active involvement in reviving the organization’s original focus on building and flying rockets, albeit in today’s tempered form of model rockets regulated by legislation.

Model rockets do nonetheless offer the distinct advantage of combining theory teaching with quickly getting to a flying rocket to keep its practitioners fired up. Over time it may even become possible (allowable) to equip (extend) these model rockets with instrumentation facilitating remote control and in-flight data collecting thus furthering the group’s understanding and motivation while helping to sustain their pursuit of rocketry. Modern day technology offers rocket hobbyist affordable choices of miniaturized inertial navigation platforms; multichannel telemetry equipment; magnetometers and accelerometers; and the likes. And lest we forget, amateur astronomers with modest means have lent their names to comets missed by the big boys!